Scaling up science with the Earlham Biofoundry

State-of-the-art automation platform, alongside analytics infrastructure and a talented team of experts, make the Earlham Biofoundry a top resource for the UK biology and biotechnology communities.

The Biofoundry exists to provide a platform to undertake large-scale projects. It supports large scale, high throughput engineering of biological systems; promotes the use of automation; and advances bioscience research and innovation in the UK.

It is home to experts in synthetic biology approaches, large-scale experiment design, and automation programming. It also offers a suite of cutting-edge equipment - out of the financial scope of most individual research labs - for collaborative projects or provided as a service.

“We offer a dual support service,” says Earlham Biofoundry manager Carolina Grandellis.

“As well as the day-to-day work to deliver projects, we collaborate with industry and academia. We are always optimising procedures and coming up with new ideas.”

“We offer automation and synthetic biology resources, as well as the chance to apply for grants in collaborative efforts.”

The Biofoundry works with a number of different biological systems - bacteria, fungi, cyanobacteria - and has developed protocols for a wide range of research interests.

These include creating genetic libraries, designing and producing synthetic DNA constructs, assembling constructs for delivery to plants for gene editing, optimising growth of engineered bacteria, and screening mutants with automated assays.

The BioLector, for example, is an automated microfermentation platform that allows fermentation of very small volumes (less than 2ml) for rapid assessment of strain behaviour and performance under various cultivation conditions.

The platform offers online monitoring of biomass, pH, oxygen dissolved in solution, and fluorescence. It also provides the option of using microfluidics to feed the growth chambers, allowing the continual control of pH, nutrient, or substrate levels, among other things.

BioLector Pro Microfermentation Platform

Akrtic automated sample storage platform

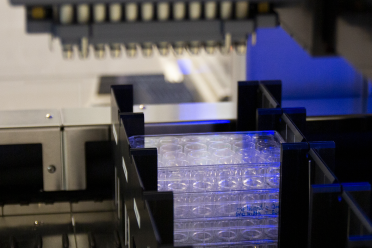

The Hamilton liquid handling system

An automated -80°C storage unit, called the arktic, can store 80,000 samples. Each sample is labelled with a unique barcode and then stored away for future use.

Operationally, it works in a similar way to a vending machine - provide the barcodes of the tubes you need and it will quickly retrieve them.

Elsewhere, the Echo 550 is a liquid handling robot that, instead of using tips, uses the energy of sound waves to transfer droplets of liquid - or even cells.

The sound waves are focused on the surface of the liquid in the source plate, stimulating precise nanodroplets (as small as five nanolitres) to leap from the plate well and arrive at the destination plate, which is inverted above the source plate and moved to the correct position.

This instrument allows the scaling down of the volume of PCR and DNA assembly reactions by several orders of magnitude.

The Biofoundry also houses four open-source Opentrons lab robots, which are designed to automate repetitive lab pipetting tasks - anything from aliquoting media to whole DNA preps, setting up PCRs, or cherry-picking from a spreadsheet as input.

We offer a dual support service, as well as the day-to-day work to deliver projects, we collaborate with industry and academia. We are always optimising procedures and coming up with new ideas.

Dr Carolina Grandellis, Earlham Biofoundry Manager

The Earlham Biofoundry is one of several foundries in the UK. Others include Genemill in Liverpool, Manchester SynBioChem, the London DNA Foundry at Imperial College, and the Edinburgh Genome Foundry.

The Earlham Biofoundry, however, exists as a National Bioscience Research Infrastructure (NBRI), receiving strategic funding from the Biotechnology and Biological Sciences Research Council (BBSRC), part of UKRI.

It is one of two NBRIs housed at the Earlham Institute, the other being Transformative Genomics - offering specialist facilities, equipment, and expertise in genomics and bioinformatics.

Alongside the Earlham Institute’s data science infrastructure and Advanced Training programme, the Earlham Biofoundry provides the UK bioscience community with access to cutting-edge tools and technology, operated by experienced and talented staff.

The NBRIs are fundamental to the research conducted at the Earlham Institute. They play a central role in the Institute’s strategic programmes - Decoding Biodiversity and Cellular Genomics - and offer a valuable resource for all research groups at the Institute, as well as external collaborators.

Cellular Genomics builds on pioneering new approaches to single-cell genomics, while Decoding Biodiversity addresses the urgent need for tools, standards, and expertise to translate complex biological information from DNA sequencing into global benefits.

Over the next five years, the Biofoundry will be providing access to expertise and hardware required for large-scale experimentation in molecular biology and biotechnology, as well as heavily supporting the institute ISPs.

The Biofoundry is building a large barcoded-DNA library for Cellular Genomics, aiming to understand cellular identities during stem cell differentiation. For Decoding Biodiversity, the Biofoundry will use automated processes to reconstruct plant genetic pathways for candidate genes that produce relevant natural compounds.

The team, under the guidance of Dr Grandellis, will also develop and provide new automated workflows, specialising in designing and assembling DNA and the engineering and characterisation of biological organisms.

Dr Anja Nenninger is a visiting scientist from the University of East Anglia (UEA). Dr Nenninger is using the Earlham Biofoundry to create the first full barcoded mutant library for the model cyanobacterium Synechocystis.

She says the staff can offer scientists a vast amount of experience and resources for complex experimental designs.

“At the Earlham Biofoundry, there is much more of a research perspective as well as the equipment,” she says. “This is the place to come if you are developing a completely new protocol from scratch.

“The Biofoundry team can develop it, advise you, and offer ideas. There are some truly excellent and very talented staff on hand.”

The Biofoundry offers a unique combination of expertise, facilities, training, and technology and interested collaborators are encouraged to get in touch.

The team can also provide training in laboratory automation through practical sessions, laboratory placements, training courses, and by hosting collaborators within the Earlham Biofoundry.

To find out more about how you can work with the Earlham Institute, discuss applying automation to your project, or to get a quote for one of our automated workflows, visit our Engage With Us page or contact us.

Opentrons platform suited for smaller scale experiments

Lesley and Carolina with the Hamilton platform

The Echo 550 nanoscale liquid handling transfer platform